资料 牺牲阳极简介

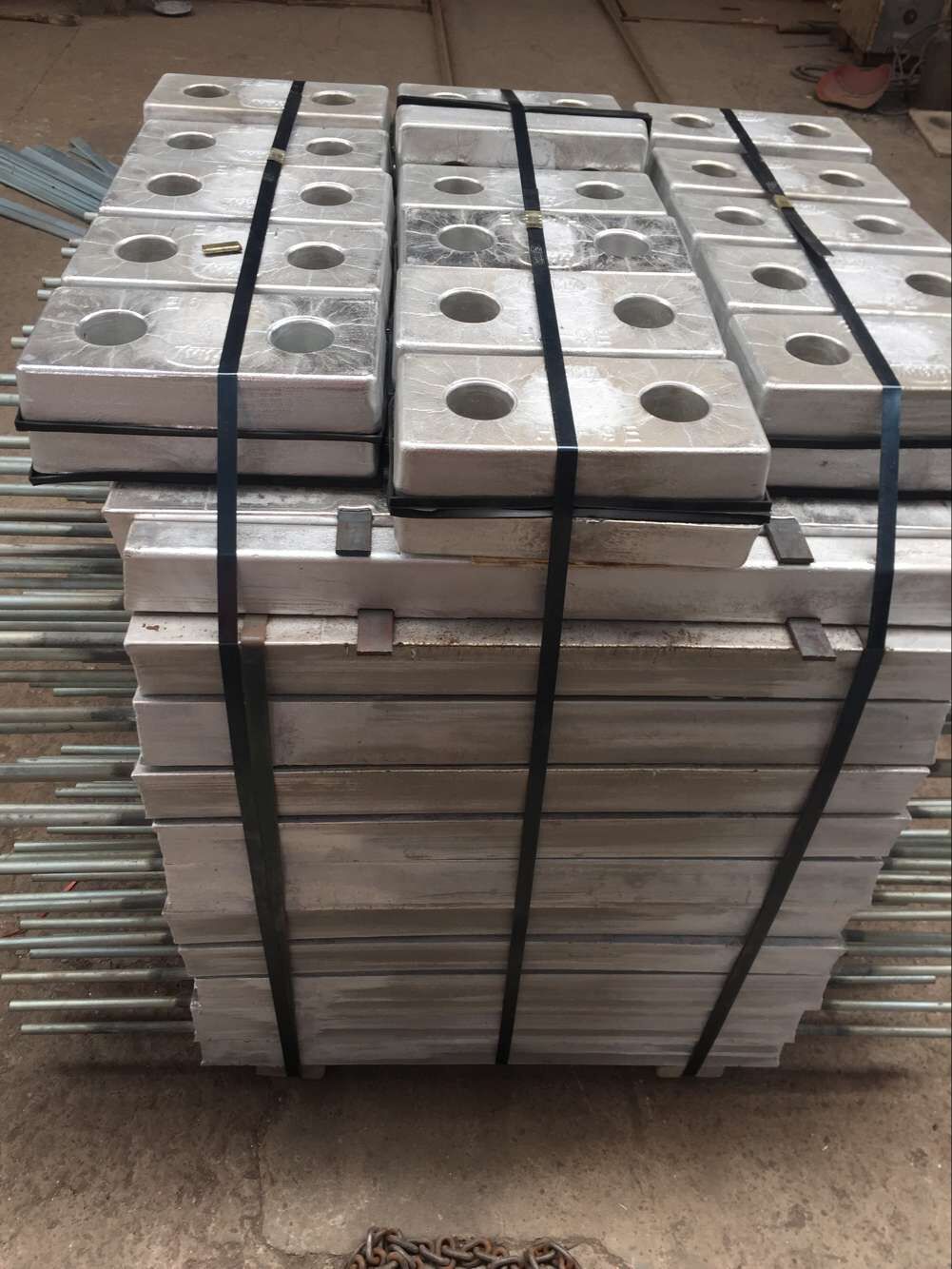

Aluminum Anodes

High Capacity Aluminum Sacrificial Anodes for Shipping & Offshore Industries

Aluminum anodes are cast in low-iron high efficiency aluminum alloys. HAISHUN anodes are characterized by lightweight and high amperage output.

Features & Benefits

· Improved Corrosion Protection is provided by HAISHUN higher driving potential compared to zinc or aluminum/mercury alloys.

· Lower Cost per System is achieved because HAISHUN greater efficiency means fewer anodes are needed, saving on material and installation labor costs.

· Optimal Composition, Quality & Fit is ensured with anodes designed and manufactured at HAISHUN own foundry.

· Bulk Melter enables the production of anodes in excess of 1,000lbs.

· Purity Matters. Contaminants like iron reduce anode life and effectiveness, are the purest available, offering exceptional corrosion protection:P0404 Alloy – the purest, premiu

· low-iron aluminum alloy for offshore structures and other applications demanding high performance and extended anode life. Contains MAX 0.04% silicon and 0.04% iron.P0506 & P0610 Alloys – low-iron aluminum alloys offering superior performance for most marine applications.

· P0506 contains MAX 0.05% silicon and 0.06% iron. P0610 contains MAX 0.06% silicon and 0.10% iron.

Applications

· Hulls and tanks of ships · Fixed offshore structures · Semi-submersibles · Pipelines · Piers

|

Installation & Operation of Aluminum Anodes

Aluminum anodes are normally clamped or welded into position from an integrated steel core. Aluminum Anodes can be installed by customer maintenance personnel in accordance with HAISHUN supplied layout drawings.

With proper installation, Aloline anodes will operate efficiently and economically without attention. They generate their own current and work silently and surely to control corrosion. Apart from routine inspection, no labor costs are involved after installation and no electrical supply is required.

Aluminum Anodes are simple and economical

Designed specifically for reliable performance under a variety of environmental conditions, |

Zinc Anodes

Zinc Anodes for Shipping & Offshore Industries

Characteristics

Zinc anodes (Zincoline) are cast in Special High Grade high purity alloys. Zincoline anodes are the ideal corrosion protection solution where the use of aluminum anodes is restricted, as in the upper areas of tanks

· Economical and Time-Tested, Zincoline anodes set the standard for affordable corrosion protection. · Optimal Composition, Quality & Fit is ensured with anodes designed and manufactured at HAISHUN own foundry. ·

|

· Pit-Guard Anodes stop corrosive pitting in cargo and ballast tanks simply and economically.

· Zincoline Alloys include the latest Mil-Spec delivering trusted performance, as well as Special High Grade for reliable protection wherever Mil-Spec is not required.

· Immediate Delivery of large quantities of standard anodes is available from stock.

· Custom Zinc Anodes can be produced to satisfy unique specifications

· · Ship hulls · Ballast tanks · Sea chests · Engine rooms · Pipelines

|

Installation & Operation

Zinc Anodes (Zincoline) are normally clamped or welded into position from an integrated steel core. Zinc Anodes can be installed by shipboard maintenance personnel in accordance with HAISHUN-supplied layout drawings.

With proper installation, Zincoline anodes will operate efficiently and economically without attention. They generate their own current and work silently and surely to control corrosion. Apart from routine inspection, no labor costs are involved after installation and no electrical supply is required.

Zinc anodes are simple and economical

Designed specifically for reliable performance under a variety of environmental conditions, Zincoline operates effectively at both low and high temperatures. HAISHUN sacrificial anodes are performance-proven with years of research and commercial use.

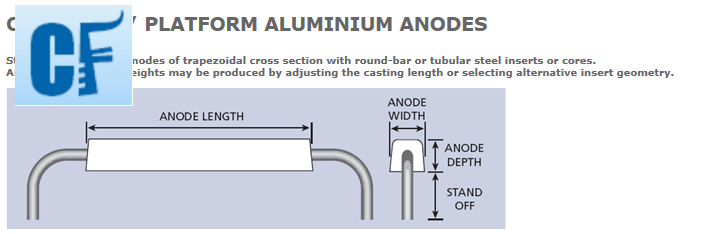

OFFSHORE / PIPELINE

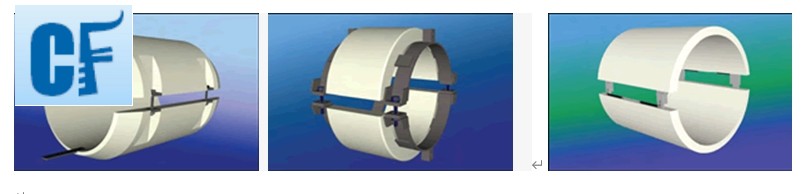

Haishun has extensive experience in submarine pipeline protection using both half shell and segmented bracelet anodes.

Bracelet anodes can be produced in the range 2” to 56” diameter and weight range typically 5kg to 1000kg. In addition, bracelet anodes can be made to any practical design with a variety of fixing and electrical continuity methods.

It is Haishun's recommended practice that adequate insert design forms part of any bracelet design to ensure that the anodic material is well supported in later life, so ensuring continual protection of the pipeline.

Special bracelet anode designs are produced for flexible pipeline end fittings with customised connection cable arrangements. Conventional half-shell bracelets can be made with either square or tapered ends and some typical bracelet designs are shown on this page.

上一篇:没有了!

售前咨询专员

售前咨询专员